Weekly projects and monthly challenges

Original clay collected from Valldaura. Notice the high percentage of small particles, such as sand, which made it challenging to find the right water to substance mix ratio.

Original clay collected from Valldaura. Notice the high percentage of small particles, such as sand, which made it challenging to find the right water to substance mix ratio.

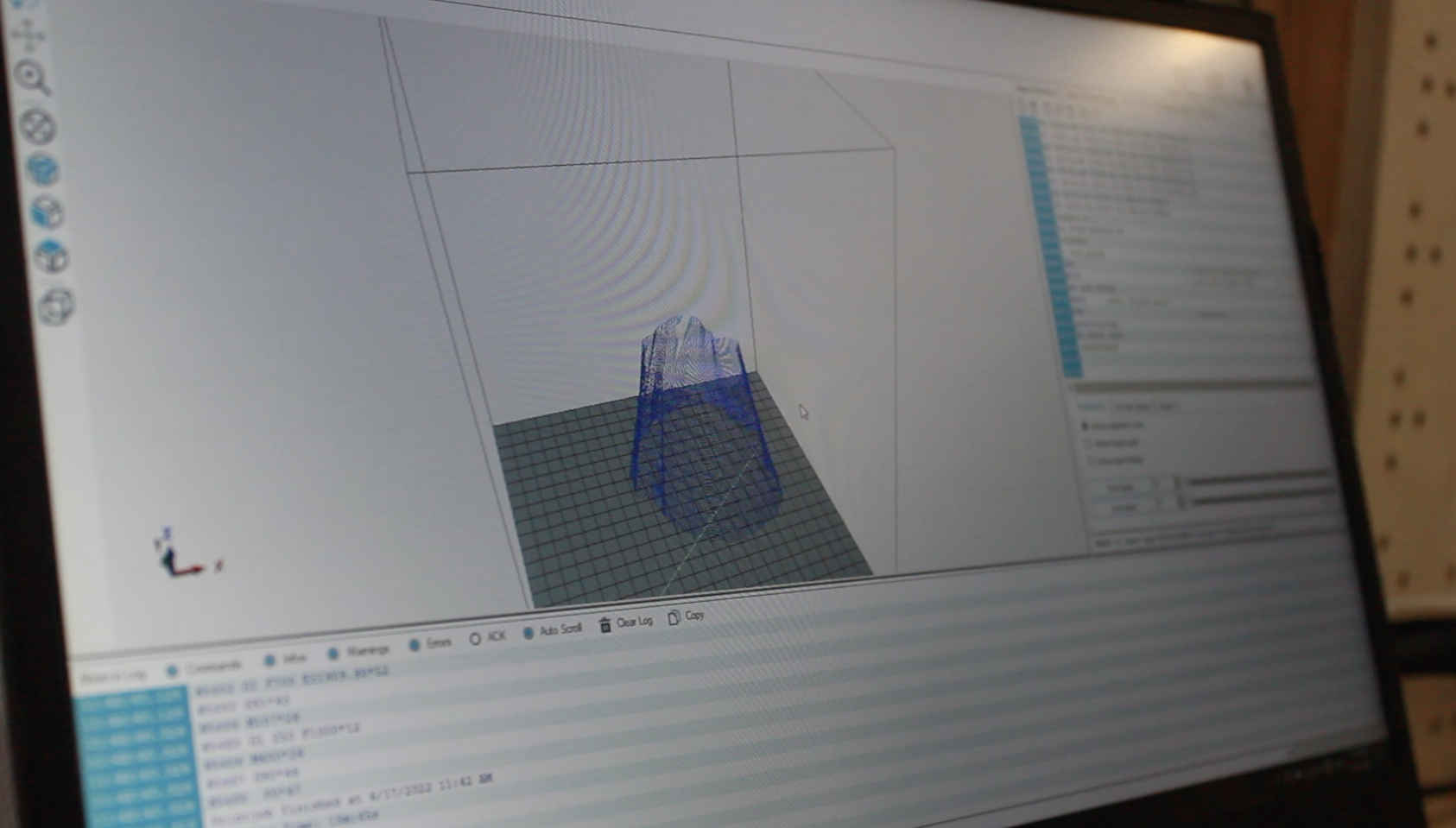

Lofting two slowed-down sound waves to generate the 3D volume.

Lofting two slowed-down sound waves to generate the 3D volume.

Monitoring the pressure provided by a compressor going into the clay cartridge. This is necessary to feed a continuous stream of substance into the modified extruder of the Ender 3, where a spindle controls the final outflow of material.

Monitoring the pressure provided by a compressor going into the clay cartridge. This is necessary to feed a continuous stream of substance into the modified extruder of the Ender 3, where a spindle controls the final outflow of material.

Here, the quality of the print can be seen close-up. This object was not printed with the Valldaura clay but with the standard industrial red clay typically used in pottery.

Here, the quality of the print can be seen close-up. This object was not printed with the Valldaura clay but with the standard industrial red clay typically used in pottery.

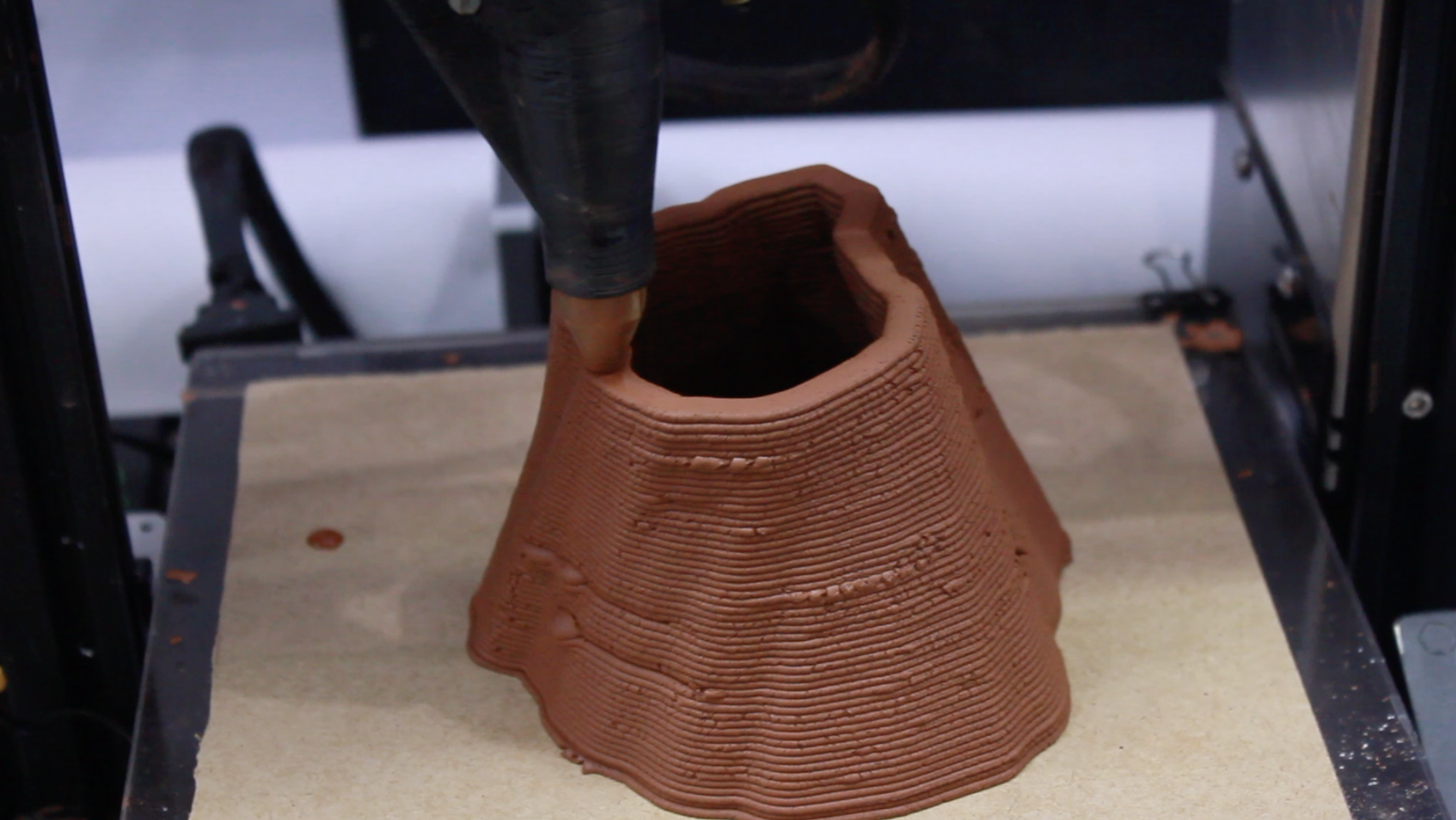

An object close to completion, while printing. Notice the increased print line width to achieve a more stable result.

An object close to completion, while printing. Notice the increased print line width to achieve a more stable result.